Volume 3 Changes in Applications Using Li-ion Batteries

-Customer Transition along with Application Expansion-

-Customer Transition along with Application Expansion-

In the last time, I talked about how the performance and packages of protection ICs developed along with market needs and technological advancement. In this volume, I will tell you about the expansion of applications using Li-ion batteries and the transition of customers using our protection ICs.

★

The world’s first application adopting so-called “Li-ion battery” was portable video cameras launched in 1992, and that type of battery also started to be equipped in handy terminals a little later. Mobile phones and laptop PCs, which were expected to make tremendous market growth at that time, also adopted Li-ion batteries. However, some of those applications had used large-capacity, environmentally friendly nickel metal hydride batteries which had been put to practical use about two years before Li-ion batteries and expected to replace nickel-cadmium batteries that had been conventional representative small secondary batteries. As two new batteries appeared almost at the same time, there were some periods when adopted batteries were different (nickel metal hydride batteries or Li-ion batteries) according to models even among same applications.

| Battery Type | Nominal Voltage | Key Features | Applications |

|---|---|---|---|

| Nickel-cadmium battery | 1.2 V |

|

|

| Nickel metal hydride battery | 1.2 V |

|

|

| Li-ion battery | 3.2 V to 3.8 V |

|

|

- *A phenomenon where charge capacity decreases gradually when a battery is charged additionally with battery energy remaining.

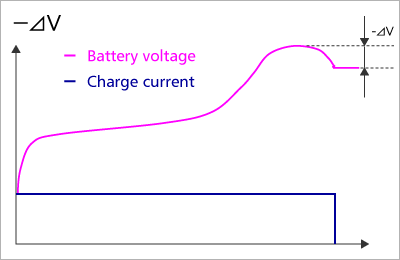

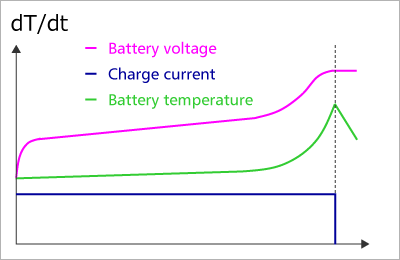

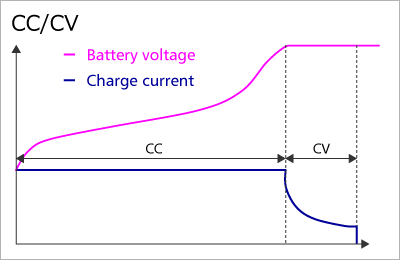

Nickel metal hydride batteries and Li-ion batteries adopt different charging control methods from each other. While charging of nickel metal hydride batteries is controlled by -ΔV method or dT/dt method in general, CC-CV method is used for Li-ion batteries. For instance, some mobile phones of a manufacturer adopted charging systems that could correspond to both batteries, and we were required to provide protection ICs the specifications of which went with such a system.

Difference of Charging Methods

-

-ΔV method:When a battery is almost fully charged, charging turns off by detecting decrease in battery voltage.

-

dT/dt method:Charging turns off by detecting increase in battery temperature at full charge.

-

CC/CV method:Constant current charging until the battery is fully charged, and constant voltage charging when the battery is almost full charged.

Also, early mobile phones were equipped with two Li-ion batteries in serial, because one Li-ion battery could not output enough voltage to power the system. However, the enormous needs for small-size and light mobile phones facilitated the improvement of power supply systems of phones, which made all the mobile phones operated with only one Li-ion battery.

Except mobile phones and laptop PCs , the use of Li-ion batteries also expanded to digital cameras and portable video games. During this expansion, mobile phones were replaced by smartphones and tablets, which also use Li-ion batteries. This is how Li-ion batteries have made a rapid growth mainly in IT devices.

In this way, Li-ion batteries prevailed from IT devices, and the spread also occurred in other applications except the IT field, especially in powertrains. Various applications including vehicles, home appliances and so on use power systems with Li-ion batteries: for example, assisted bicycles, electric motorcycles, transfer robots, power tools, stick or robot vacuums, electric toothbrushes, shavers, e-cigarettes and hearing aids. The remarkable application is vehicles, as they are the largest application that will facilitate the Li-ion battery market to expand in the future. At first, vehicles also adopted nickel metal hydride batteries, but the adoption of Li-ion batteries has been increasing steadily. In particular, Company T , located in the United States, realized a breakthrough by equipping their electric vehicles with over 7,000 18650-size Li-ion batteries which are usually used in portable devices. I could never come up with the idea to get a car operated with dry-cell-size batteries.

-

Using over 7,000 18650-size Batteries Manufactured by Company T

As various applications came to adopt Li-ion batteries, customers for us IC manufacturers gradually changed, too. Li-ion batteries were said to have risks of heat generation and firing by overcharge, short circuit, etc. from the very beginning of market launch, so battery cells alone were never sold even to B-to-B customers; they were sold only in the style of battery packs with protection circuits constructed by battery manufacturers. This means that battery manufacturers not only developed battery cells and packs but also designed protection circuits, so we IC manufacturers promoted and sold our protection ICs to battery manufacturers. However, the distribution style of Li-ion batteries changed gradually. Some manufacturers began to develop and assemble battery packs in Taiwan, which had been famous for assembly factories of PCs at that time. Also, battery cells started to be developed and manufactured not only in Japan but in China and South Korea, which made it easy to obtain naked battery cells called bare cells. This led to the appearance of manufacturers which fabricated protection circuits and cells and produced battery packs. Subsequently, the number of manufacturers specialized in developing battery packs started to increase in China and South Korea, and module manufacturers focusing solely on protection circuits emerged gradually, too. As a result, Li-ion battery pack production was divided into three and each of them was left to Li-ion cell developers, protection circuit developers, and battery pack assembly factories. In accordance with such a changing situation, we IC manufacturers changed our customers from battery cell manufacturers to protection circuit developers. The line of development has been further evolving and applications manufacturers have come to put up a development department for battery packs. Currently, a production style has become mainstream where applications manufacturers design basic circuits while factories in China and/or Taiwan assemble and produce battery packs.

In summary, as an IC manufacturer, customers in our contact lists transferred from battery cell manufacturers to battery pack manufacturers, from battery pack manufacturers to protection circuit module manufacturers, and from protection circuit module manufacturers to applications manufacturers.

At first, Li-ion batteries were released in 18650-size cylindrical-type packs, and the shape of battery packs evolved through rectangular type to pouch type. Particularly, the appearance of pouch-type battery packs enabled Li-ion batteries to be fabricated freely in size and shape, which resulted in a wider variety of applications adopting Li-ion batteries.

-

Cylindrical Type

-

Square Type

-

Pouch Type

★★

At present, many designers will first come up with Li-ion batteries as the power source when considering battery-powered systems, won’t they? I suppose the number of applications using Li-ion batteries will increase. On the other hand, I also suppose that many people are interested in how the post-Li-ion batteries will be. I hope I can talk about post-Li-ion batteries at another time.

Published July 5, 2022

Serial Content

Will Li-ion Battery Protection ICs Never Perish?

-

Future of Li-ion Battery Protection ICs

-

Measures for Trouble in Li-ion Battery Protection Circuits

-

Changes in Applications Using Li-ion Batteries -Customer Transition along with Application Expansion-

-

History of Li-ion Battery Protection ICs -Evolution of Performance and Package from Beginning to Present-

-

History of Li-ion Battery Protection ICs -Evolution of Functions from Beginning to Present-

-

-The Pioneer Says...- Will Li-ion Battery Protection ICs Never Perish?

Author profile

Akihiko Fujiwara

Nisshinbo Micro Devices Inc.

Akihiko Fujiwara has engaged himself in product planning and designing of our Li-ion battery protection ICs since 1990s, the dawn of secondary Li-ion batteries, which has made him famous in the industry. Now as an "expert in protection ICs," he devotes himself to marketing and planning and leads the path of protection ICs we should take, through collecting information on the latest trends in batteries and protection ICs worldwide.