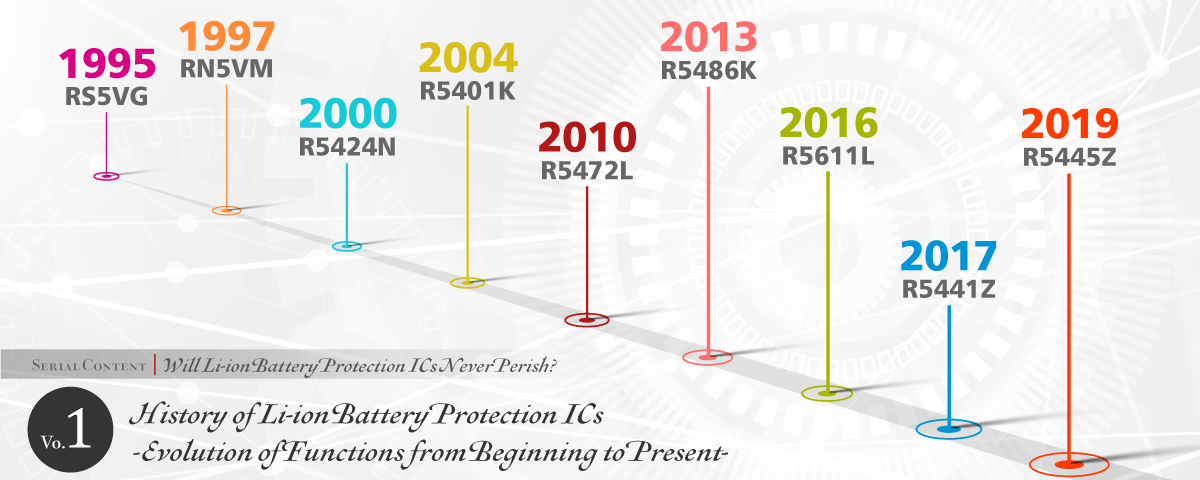

Volume 1 History of Li-ion Battery Protection ICs

-Evolution of Functions from Beginning to Present-

-Evolution of Functions from Beginning to Present-

Hello, I am Akihiko Fujiwara in Product Strategy and Planning Section, Business Strategy and Planning Department. I have worked at Nisshinbo Micro Devices as a product planner and designer of our Li-ion battery protection ICs since 1990s, the dawn of secondary Li-ion batteries.

Asked to create special content for our website, I decided to write columns concerned with Li-ion battery protection ICs. Therefore, as of June 2021, I will post a series of columns. I hope you enjoy this series.

Japanese society has started an initiative to realize carbon neutrality by 2050, and to achieve this goal, renewable energy technology has become more important than ever. It would not be an exaggeration to state that the key to successfully construct a society powered by renewable energy lies in the development of battery technology, especially the Li-ion battery technology. Although it has been common to use Li-ion batteries as a secondary battery today, battery protection ICs working behind the scenes to ensure safety, security and optimal performance of those batteries, are still essential.

In the first volume of this series, titled “History of Li-ion Battery ICs (1st Half)”, I will tell you about the changes, progress and development in the functionality of Li-ion battery protection ICs. Two years before I started writing this, I had also written another column titled “Will Li-ion Battery Protection ICs Never Perish?” on our website. Some of the topics in this new column may have already been stated in the previous one. If so, I will try to explain them in more detail.

★

Comparison and Evolution of Functions

The RS5VG, our first protection IC developed in 1995, had only three functions: overcharge detection, over-discharge detection and discharge overcurrent detection (called short detection at the time). The delay time settings are worthy of note. While the delay time of the over-discharge detection function could be configurable with an external capacitor, that of discharge overcurrent detection function was fixed internally at around 2 ms. However, as the overcharge detection function did not contain a delay circuit, it reacted to detect the overcharge within 20 to 30 µs, a delay time of the logic circuit to operate. At that time, we thought overcharge was a dangerous state, so the charging path should be cut off as soon as possible after the protective function detected overcharge. However, we had a difficult time because this overcharge detection circuit with little delay time caused huge trouble in our customers' evaluation stage. I would like to talk about it in subsequent volumes on troubleshooting.

★★

In 1997 we developed a protection IC named RN5VM, which advanced from the RS5VG by taking advantage of the lessons we learned from the previous model. This product was able to set delay time for the overcharge detection function with an external capacitor. Besides, the delay circuit of the over-discharge detection function was integrated, and double-level detection was adopted to the overcurrent detection at discharge by adding a short-circuit detection. Also, we prepared two versions to let users choose the preferred one: the 0-V battery charging permitted version or the 0-V battery charging prohibited one.

Originally, the reason why each detection function has a delay time is to prevent malfunction caused by various sources of noise. Regarding over-discharge, it became clear that around 10- to 20-ms delay was enough to prevent malfunction so we could construct the over-discharge detection delay circuit inside the protection IC. On the other hand, the delay time for overcharge needed to be in seconds based on operating conditions, so we let customers use an external capacitor to configure the overcharge detection delay time.

At that time, some mobile phones adopted a nickel metal hydride battery and the charging circuit corresponded to both a Li-ion battery and a nickel metal hydride battery. In order to discern the type of battery used, a high voltage was applied to the circuit for around two seconds, and therefore the overcharge detection function needed a delay time of around five seconds as a typical value.

The short-circuit detection function was added to make the IC respond to a short-circuit state within a short time by adding an additional threshold. The RS5VG had a discharge overcurrent detection delay time of around 2 milli-seconds, and if the circuit went 0-ohm short circuit, a large current would flow and the FET might be damaged. As with the initial notion for the overcharge detection function, the short-circuit detection function did not include a delay circuit to respond to the short-circuit state as soon as it was detected.

On 0 V battery charging, there were often conflict of opinions between battery manufacturers and mobile phone manufacturers using batteries. While battery manufacturers wanted to prohibit charging a 0 V battery because it may generate dendrites* which cause internal short-circuit, mobile phone manufacturers wanted to charge even a battery which had discharged to 0 V as the incapability of charging a battery might lead to user complaints. Although we prepared the 0-V battery charge prohibited type for the RN5VM for the first time, mobile phone manufacturers had more power to decide which type to choose than battery manufacturers at the time because they were the battery manufacturers’ customers. Therefore, the 0-V battery charge permitted type was often chosen and the 0-v battery prohibited type was seldom used. These days, however, mobile phone manufacturers also give priority to safety and security, and 0-V battery charging prohibition type is becoming the mainstream.

*Dendrites: although the word generally refers to acicular crystal, it refers to the needle-shaped deposition of lithium metal crystal. Once the dendrites are generated, they may penetrate the separator which separates the positive and negative electrodes inside a cell. This can cause internal short state, which at the worst case leads to the very dangerous thermal runaway of the battery.

★★★

The R5424N, which was launched in 2000, included a charge overcurrent detection function anew, and all the delay times were designed to be settable via internal counters. This reduced the need for external capacitors generally used to set delay times, which helped customers reduce the cost of protection circuit boards. On the other hand, there were demands for enhancing the efficiency of testing overcharge detection delay time which took several seconds, so the IC was equipped with a delay shorten pin (DS pin) for testing the overcharge detection function with the delay time shortened.

The DS pin was deleted from the R5401K, which was launched in 2004. Instead, the pin which the negative end of a charger was connected to could be used as a testing pin.

From the R5472L, launched in 2010, the overcurrent detection function was changed from the conventional method using an FET’s on-resistance to the one monitoring the voltage at both ends of an external resistor. It was difficult for the conventional method to detect overcurrent accurately because the on-resistance of an FET is highly dependent on battery voltage and temperature. By contrast, although the new method adopted in the R5472L required more external components, it became possible to conduct high-accuracy overcurrent detection by using a high-accuracy external resistor, with the temperature characteristics taken into consideration. Since then, the external resistor type has gradually become mainstream.

In 2013, a new detection function named discharge overcurrent 2 was added to the R5486L. Having three-step discharge overcurrent detection including the short-circuit detection, the R5486L made it possible to conduct more detailed detection of overcurrent. The three-step detection has different detection current values and largely different delay times respectively. The detection delay times are arranged by two-digit range: for example, the overcurrent detection 1 has five-second delay, the overcurrent detection 2 twelve-milli-second delay, and the short-circuit detection two-hundred-fifty-micro-second delay.

In 2016, the R5611L was launched with a reset pin added to control the IC externally. By asserting the reset pin high, the FETs on both the charging and discharging sides can be turned off, which makes it possible to reset the whole system.

The R5441Z in 2017 was equipped with a temperature detection function. It monitors temperature with an external thermistor and can turn off the charging and discharging control FETs when a high temperature is found. In addition, the detection temperatures are settable for the charging and discharging control FETs respectively.

The R5445Z launched in 2019 has a standby pin as a control function, which enables switching the protection IC to standby mode compulsorily by turning this pin low, and therefore makes the current consumption reduced to nearly zero. This function is helpful when, for example, a battery pack is stored in a warehouse for a long time after it is manufactured until it reaches its end-user; the function prevents the battery capacity from being reduced by the current consumption of the protection IC. Also, the R5445Z can drive an external high-side NMOSFET driver. Although conventional one-cell protection ICs commonly use low-side FETs for charging and discharging, using high-side FETs has advantage of preventing the ground line between the battery pack and the system from being cut off. This helps ease the communication with the system by using an external power supply even when the FET is off.

★★★★

Table 1 illustrates how functions of Li-ion battery protection ICs have changed.

Table 1

| 1995 | 1997 | 2000 | 2004 | 2010 | 2013 | 2016 | 2017 | 2019 | |

|---|---|---|---|---|---|---|---|---|---|

| Product Name | RS5VG | RN5VM | R5424N | R5401K | R5472L | R5486K | R5611L | R5441Z | R5445Z |

| Overcharge Detection | |||||||||

| Overcharge Detection Delay Time |

- | External C* | Internal* | Internal | Internal | Internal | Internal | Internal | Internal |

| Overdischarge Detection | |||||||||

| Overdischarge Detection Delay Time |

External C | Internal* | Internal | Internal | Internal | Internal | Internal | Internal | Internal |

| Discharge Overcurrent Detection 1 |

|||||||||

| Discharge Overcurrent Detection Delay Time 1 |

Internal | Internal | Internal | Internal | Internal | Internal | Internal | Internal | Internal |

| Discharge Overcurrent Detection 2 |

- | - | - | - | - | - | - | ||

| Discharge Overcurrent Detection Delay Time 2 |

- | - | - | - | - | Internal* | Internal | - | - |

| Charge Overcurrent Detection |

- | - | |||||||

| Charge Overcurrent Detection Delay Time |

- | - | Internal* | Internal | Internal | Internal | Internal | Internal | Internal |

| Short-circuit Detection | - | ||||||||

| Short-circuit Detection Delay Time |

- | - | Internal* | Internal | Internal | Internal | Internal | Internal | Internal |

| FET Sense / External R Sense |

FET | FET | FET | FET | External R* |

External R |

External R |

External R |

External R |

| 0-V-battery Charge Option | Available only |

Available/ Unavailable* |

Available/ Unavailable |

Available only |

Unavailable only |

Unavailable only |

Available only |

Available/ Unavailable |

Unavailable only |

| Delay Shortening Function | - | - | DS Pin* | Internal* | Internal | Internal | Internal | Internal | Internal |

| Thermal Detection | - | - | - | - | - | - | - | High Temp Dis/charge* |

High Temp Dis/charge |

| CTL Function | - | - | - | - | - | - | Reset* | - | Standby* |

| FET Control | Low Side | Low Side | Low Side | Low Side | Low Side | Low Side | Low Side | Low Side | High Side |

* New functions at the time of development

As I have so far mentioned, various functions have been added in over 20 years. I am sure the development in functions will continue to use Li-ion batteries more safely and efficiently.

Published Oct. 28, 2021

Serial Content

Will Li-ion Battery Protection ICs Never Perish?

-

Future of Li-ion Battery Protection ICs

-

Measures for Trouble in Li-ion Battery Protection Circuits

-

Changes in Applications Using Li-ion Batteries -Customer Transition along with Application Expansion-

-

History of Li-ion Battery Protection ICs -Evolution of Performance and Package from Beginning to Present-

-

History of Li-ion Battery Protection ICs -Evolution of Functions from Beginning to Present-

-

-The Pioneer Says...- Will Li-ion Battery Protection ICs Never Perish?

Author profile

Akihiko Fujiwara

Nisshinbo Micro Devices Inc.

Akihiko Fujiwara has engaged himself in product planning and designing of our Li-ion battery protection ICs since 1990s, the dawn of secondary Li-ion batteries, which has made him famous in the industry. Now as an "expert in protection ICs," he devotes himself to marketing and planning and leads the path of protection ICs we should take, through collecting information on the latest trends in batteries and protection ICs worldwide.