Featured Products - NM2101 -

Acoustic Sensor for Predictive Maintenance

October 20, 2023

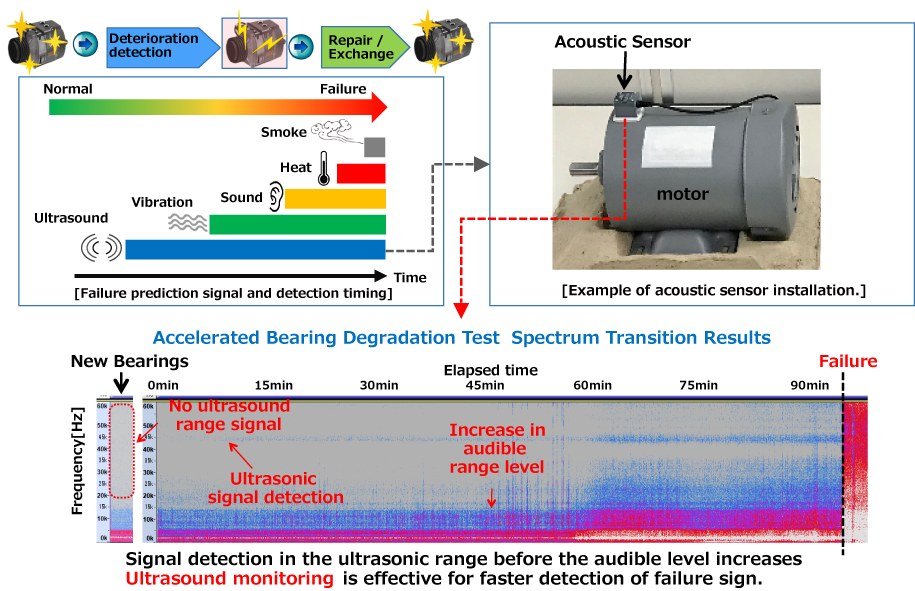

Rotating equipment used in factory production equipment has the risk of sudden production line stoppage due to failure caused by bearing wear or damage, so it is managed by regular maintenance and parts replacement depending on the usage time in general. In preventive maintenance, even usable parts are maintained and replaced, which results in wasted worker resources and parts replacement costs. Today, with the advancement of IoT in factories, shifting to status management that monitors the status of production equipment in real time using sensors can reduce maintenance costs and avoid downtime.

For the reason above, Nisshinbo Micro Devices applied MEMS sensor technology to develop an acoustic sensor that can detect everything from audible sounds to ultrasonic waves.

By monitoring ultrasonic waves, it is possible to detect signs of failure earlier.

Features

-

- Ultrasonic sensor for environmentally resistant industrial applications.

- Detects ultrasonic waves up to 100kHz.

- Dustproof and waterproof IP67.

- Contact installation type to suppress ambient noise.

-

* Currently only in Japanese. English version in progress

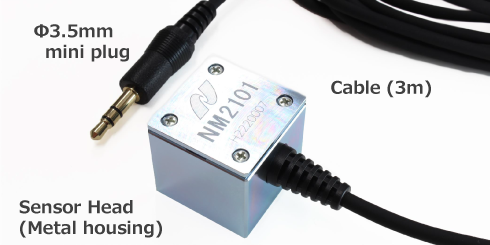

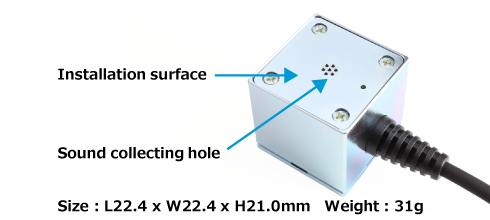

Appearance

Main functions / Characteristics / Specifications

Main functions

Main features

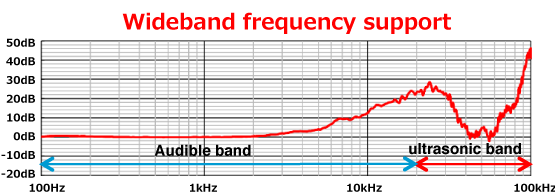

- Can detect everything from audible sounds to ultrasonic waves.

- Achieves flat sensitivity in the 100-100kHz band.

- Excellent environmental resistance.

- Waterproof and dustproof IP67 (at the time of waterproof construction).

- Highly environmentally resistant stainless steel housing.

- Environment resistant cable used (oil resistant, chemical resistant, UV resistant).

Easy to use

- Insulates ambient noise due to contact installation.

- No special mount required (no drilling or threading required).

- Voltage output with line amplifier.

- With cable (3m).

Application

- Detection of signs of failure in motors, pumps, etc.

- Metal processing quality control, cutting tool management.

- Hitting sound inspection, operation sound inspection.

- Gas leak and water flow detection.

Characteristics

Specifications

| Item | Setting / Value Ta:25℃ |

| Supply Voltage | 2.5V to 3.6V |

| Consumption Current | Less than 1mA / 3.0V |

| Output | Single-ended voltage output |

| Microphone Sensitivity | -36dB/Single, 94dB SPL @10kHz |

| Frequency Range | 100 to 100kHz |

| Operating Temperature Range |

-14℃ to 105℃ |

| Gain Setting | 0dB |

| Dustproof And Waterproof | IP67 (When waterproofing with adhesives) |

| Highly Weather Resistance | Oil-resistant, chemical-resistant, UV-resistant |

| Size L22.4 x W22.4 x H21.0mm | |

| Weight 31g | |

| Cable Length | 3m |

| Plug Shape | Φ3.5mm 3-pole mini plug |

| Non-waterproof |

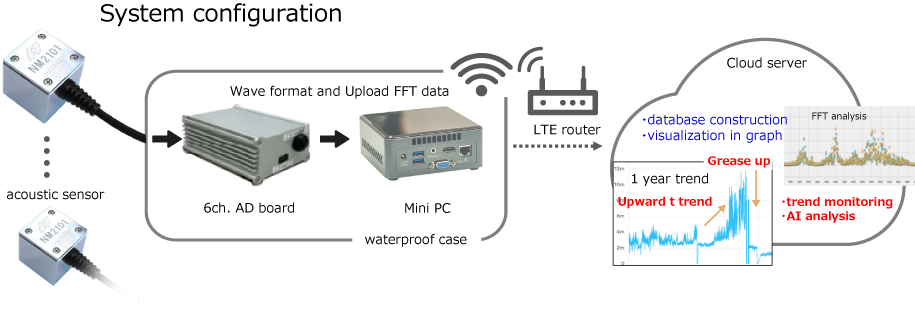

Case study

Step towards solution services

Efficacy of Ultrasound Monitoring

Demonstration video

-

- 1. Sensor installation and setup.

- 2. Bearing operation sound measurement.

- 3. Verification of changes in operating sound due to bearing lubrication.

-