Supporting your IoT system construction

Battery monitoring

Supporting your IoT system construction

Power management IC capable of battery voltage monitoring

Battery voltage monitoring with built-in resistance divider

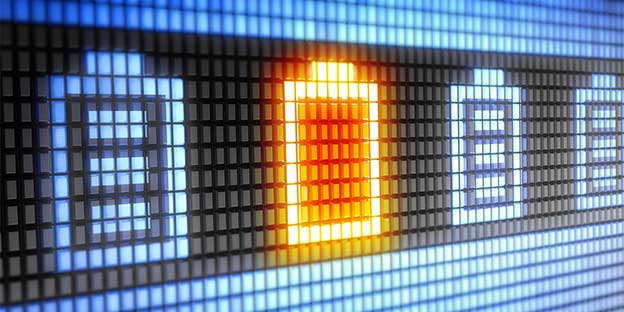

With expansion of IoT market, IoT devices with sensors, microcomputers, ICs for communication devices and so on are required to provide long-term battery operation and smaller size.

Furthermore, these IoT devices are facing increasing demand for battery voltage monitoring.

Incorporating battery voltage monitoring into power management IC helps to reduce the size, prolong battery life and contribute to long-term operation of IoT devices.

Nisshinbo Micro Devices’s power management IC capable of battery voltage monitoring helps to reduce the size, prolong battery life and contribute to long-term operation of IoT devices.

The power management IC with the battery monitor pin helps to decrease the number of IoT application’s components and brings the reduction of the leakage current. Since this leakage current is closely related to battery lifetime, reducing current supply for a whole system leads to longer battery lifetime, long-term operation then reduction in labor hour for battery exchange.

By the battery voltage monitoring with high-accuracy of ±20mV, the increment of supply current is externely small, 0.1 µA or less even if the monitoring is added.

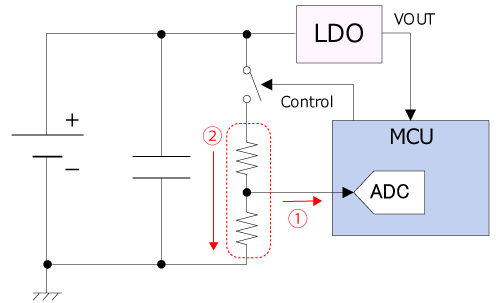

vs. CONVENTIONAL (ex.: RP124)

CONVENTIONAL: an external resistance divider

Since the input impedance of the A/D converter built in the MCU (1) is low, the impedance of the resistance divider (2) must be low as well. Thus, the amount of current flow to the ground at the resistance divider would be large and that leads to a large current supply for a whole system. Furthermore, external circuits and control signal wires require larger mounting area.

- The whole system requires large amount of current supply.

- The accuracy of the battery voltage is low.

- The mounting area for external components is large.

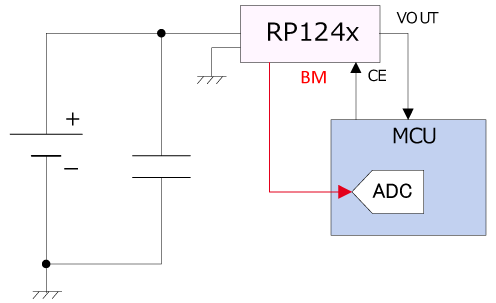

RP124: with a battery monitor function

The battery voltage is divided inside the RP124 then output from the BM pin. The divided voltage is optionally set to 1/3 or 1/4. No external components, so mounting area can be smaller.

- The accuracy of voltage will improve.

- The ultra-low current supply will realize long life operation.

- It will reduce mounting area

Example of the battery monitoring

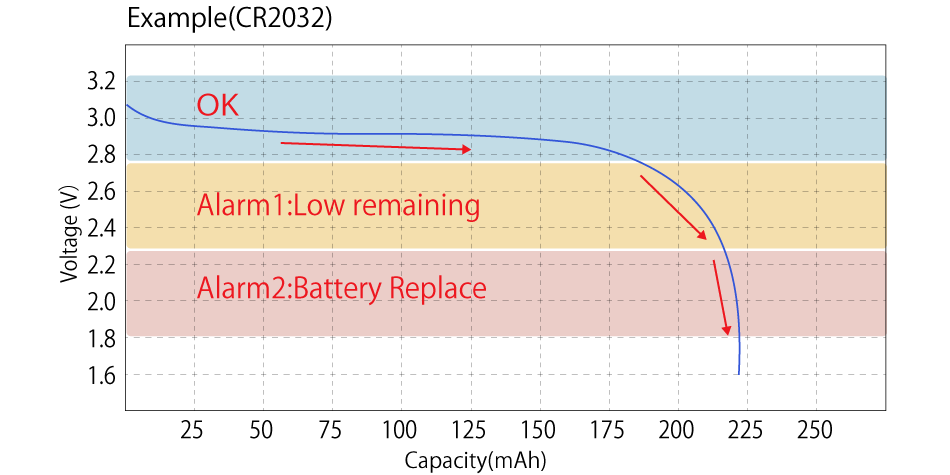

The ADC built in the MCU measures the buffer output of 1/3 or 1/4 of the battery voltage and it makes possible that the remaining charge left in the battery is displayed corresponding to three grades.

Low supply current power management IC with the battery monitor function

RP124 Series

The RP124 is a low supply current LDO regulator with a battery monitor (BM).

The battery monitor works as a resistance divider and provides 1/3 or 1/4 of the input voltage (Vin) to monitor the remaining charge left in the battery of a device such as MCU.

Buffer output enables signals to be input directly into the low voltage A/D converter (AD) built in the MCU.

| Product Name | Function | ISS | IOUT | VIN |

|---|---|---|---|---|

| RP124 | Low Supply Current LDO Regulator with Battery Monitor | 0.3 µA | 100 mA | 1.7 V to 5.5 V |

| RP515 | Low Supply Current Buck DC/DC Converter with Battery Monitor | 0.4 µA | 300 mA | 1.8 V to 5.5 V |

| RP605 | Low Supply Current Buck-boost DC/DC Converter with Battery Monitor | 0.4 µA | 300 mA | 1.8 V to 5.5 V |