Featured products

Two Laser Diode Driver ICs for Head-Up Display and Pico Projector applications

March 3, 2020

Nisshinbo Micro Devices owns many patents and has years of experience in developing laser diode driver ICs, because such products are widely used in our world-famous office laser copiers and printers. Laser driven projectors are now also becoming popular to use in specific automotive and consumer equipment, such as ADAS head-up displays for car dashboards and in portable pico video projectors to view presentations and films. This change is a result of technology advances in electronics integration, ultra-small IC packaging and light sources.

Laser projectors have significant advantages over conventional displays using LEDs, their color range is twice as large and its contrast ratio is much better for a crystal clear visibility of the displayed content.

LCD & DLP versus Laser projection

Today’s automotive HUD systems are mainly equipped with LCD display panels. The image is first loaded into the LCD screen and the background is illuminated by powerful LEDs. The dark areas are created by blocking the backlight, but not all light can be completely blocked by the LCD filter and this is especially noticeable in environments with low ambient light.

The result is a projected image with a transparent postcard sized rectangle. Car manufacturers see this as an important safety disadvantage because the illuminated rectangle distracts the driver.

LCD-based HUDs have a limited field of view and resolution. To increase the field of view, a larger LCD panel would be required and with a higher resolution to achieve a good visual quality of the augmented reality, resulting in a higher electrical power consumption to illuminate this larger screen.

DLP-based HUDs offer better resolution because it has thousands of movable micro mirrors for each pixel. The light source is projected onto the mirrors that are modulated to reflect the light to the screen with the right intensity. A dark pixel simply does not reflect its light to the screen, thus avoiding the postcard effect as with LCD HUDs.

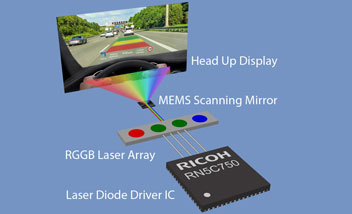

In a laser scanned projector, every pixel is pulsed very quickly to achieve a full HD resolution. A MEMS scanning mirror reflects the light at the correct position on the screen. Because the laser beam is always in focus, the image can be projected onto the windshield without having to refocusing optics. This considerably reduces the overall complexity and size of the optical system and eliminates expensive components and assembly.

Another important advantage of laser projection is that it offers a much better electrical efficiency, it only illuminates the content on the screen that needs to be projected. The dark or off pixels require less or no power, whilst LCD or DLP-based projection systems initially illuminate the entire projection area.

Nisshinbo Micro Devices’s Laser Diode Driver ICs

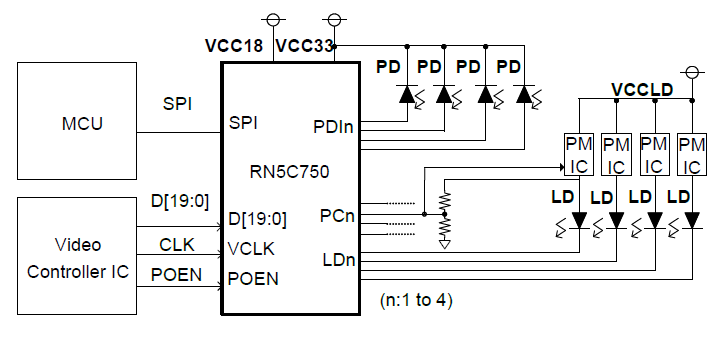

The RN5C750 and RN5C752 are four-channel laser drivers that have been developed for use in RGB or RGGB laser scanning type screens and are equipped with many functions.

Offers a full HD resolution (1080p) and 60 fps image thanks to a fast laser diode output of 200 megapixel / sec and a high output current of up to 800 mA (LD1) and 400 mA (LD2-4). The laser diode outputs are able to tolerate voltages up to 10 V to make it possible to use laser diodes with a high forward voltage. In addition, power control for the laser diodes is performed by automatically adjusting the power source to save power and minimize heat dissipation. Contains various protection circuits such as laser diode overcurrent and short detection, thermal shutdown and photodiode overcurrent detection.

The RN5C750 has passed the AEC-Q100 (Grade 2) compatible reliability tests for automotive purposes and has a guaranteed operating temperature range from -40 to +105°C. The RN5C752 is an identical IC for consumer applications and has a temperature range from 0 to +70°C.

A special feature adopted from professional laser printers is used to deliver a high-quality output regardless of temperature. By using four additional photodiode sensors connected to the IC, it is possible to automatically detect the threshold current (Ith) and light emitting current (Icolor) of each channel and maintains its color range regardless of temperature fluctuations.

Both products are available in the same QFN0808-56 package with a wettable flank technology, it improves the solderability of the chip and enables better automatic visual inspection of the solder joint after mounting on the printed circuit board. 7 bits dimming is possible by a simple setting in a specific register; there is no need to adjust the video data stream. Samples and evaluation boards are available through our global local distribution network.

To be used in:

Due to the smaller size and the simple optical requirements, it is possible to replace existing solutions. It is assumed that laser scanning projection is most suitable for the next generation of automotive augmented reality HUD systems. In the field of digital video projection, the demand for portable laser scanning pico projectors is also expected to increase in the near future due to the compact size and focus-free features.

Conclusions

The new laser diode driver ICs are a newly added category in our product portfolio and have until now only been used for internal purposes, such as in copiers and printers. We estimate major market interests because this type of technology is quickly becoming popular. The optical and power consumption functions have significant advantages over the currently available solutions and the costs of such advanced laser systems are becoming affordable nowadays.

-

Key Features and Specifications of RN5C750

4ch RGB Laser Diode Driver for Display System, for Automotive Applications

-

Key Features and Specifications of RN5C752

4ch RGB Laser Diode Driver for Display System

-

Distributors

Please contact your local Distributors for any sales-related inquiry such as price.