Actively investing to establish a third pillar of revenues alongside op-amps and power ICsThe evolution of Nisshinbo Micro Devices’ light sensor modules is being driven by the trinity of circuits, devices, and packaging

Nisshinbo Micro Devices is working to strengthen its module business, which blends circuit, device, and packaging technology. Within this it is developing distinctive products using light sensor modules built around the optical semiconductors in which it has built a track record of high value-added products for more than forty years.

Strengthening the module business as a comprehensive analog semiconductor manufacturer.

Nisshinbo Micro Devices was born from the business integration of New Japan Radio Co., Ltd. and RICOH Electronic Devices Co., Ltd. in 2022. It began life as a comprehensive analog/mixed signal semiconductor manufacturer incorporating the op-amps and other signal processing analog ICs that were the strength of New Japan Radio, and the regulators and other power supply ICs that were the specialty of RICOH Electronic Devices.

Through business integration, Nisshinbo Micro Devices aims to become a prominent analog solutions provider. Source: Nisshinbo Micro Devices

While seeking to bring value-added products to its customer base, Nisshinbo Micro Devices, in addition to broadening its lineup of signal-processing analog ICs and power supply ICs, is engaging in full-fledged development of module products that combine such ICs. The resulting devices will provide system solutions consisting of modular products with embedded software and other elements. The ultimate goal is to provide solutions built around a core of analog/mixed-signal semiconductor technology that offers greater value to users.

By blending the circuit, device, and packaging technology developed by New Japan Radio and RICOH Electronic Devices, the module business, which Nisshinbo Micro Devices has been hastening to strengthen since it began operations, seeks to provide a higher level of value that would be difficult to achieve through ICs alone. In addition to establishing the Module Design Department as an organization dedicated to the development of modules, in 2022 Nisshinbo Micro Devices began operating packaging lines dedicated to module products at its backend process site Nisshinbo Micro Devices AT (Saga prefecture).

Optical semiconductors with a track record exceeding forty years in the high value-added end of the market.

Ippei Noda, General Manager of the Module Design Department in the Technology Development Division.

The area of greatest focus within this modularization endeavor has been light sensor modules built around optical semiconductor technology. Ippei Noda, General Manager of the Module Design Department in the Technology Development Division, notes that although op-amps and power ICs are their mainstay products, they also have a track record exceeding forty years in optical semiconductor products. Using the trinity of circuit, device, and packaging technology to modularize the fundamental technology related to optical semiconductors developed over the years, Nisshinbo Micro Devices will further drive their evolution, and build optical semiconductors and light sensor modules into a third pillar of revenues alongside op-amps and power ICs. “By 2026 we will increase net sales of optical semiconductors and light sensor modules to twice the level of 2023,” he says.

The optical semiconductor business of Nisshinbo Micro Devices began around forty years ago, when New Japan Radio entered the near infrared LED market. During the first half of the decade following the turn of the millennium, Nisshinbo Micro Devices gained a certain market share in photoreflectors for detecting lens position in mobile phones equipped with cameras, which had just begun to appear in the market. With the slowing of the spread of mobile phones with built-in cameras and smartphones, price competition for photo reflectors became increasingly intense. So Nisshinbo Micro Devices moved its focus to providing opto-semiconductor products used in interchangeable lenses for digital SLRs, industrial equipment, and robots,

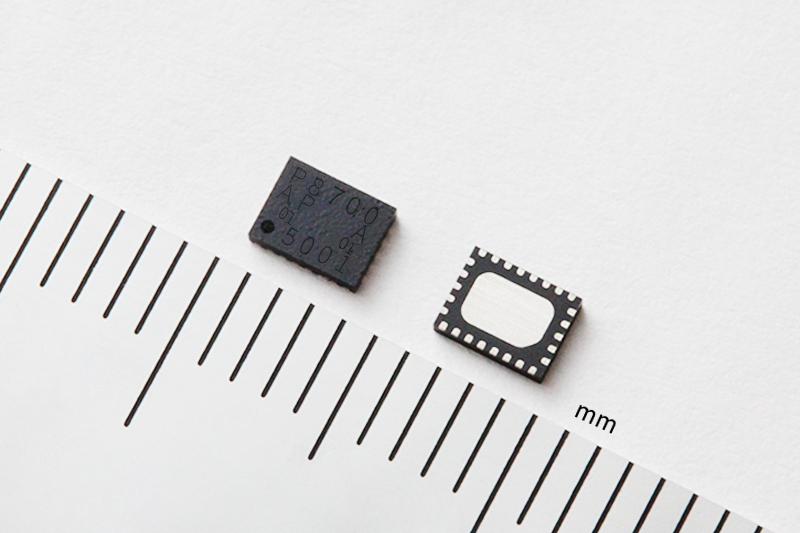

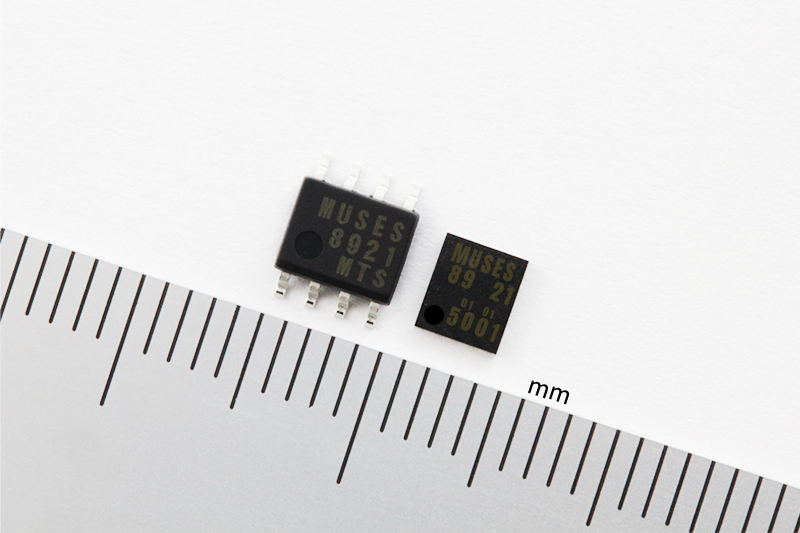

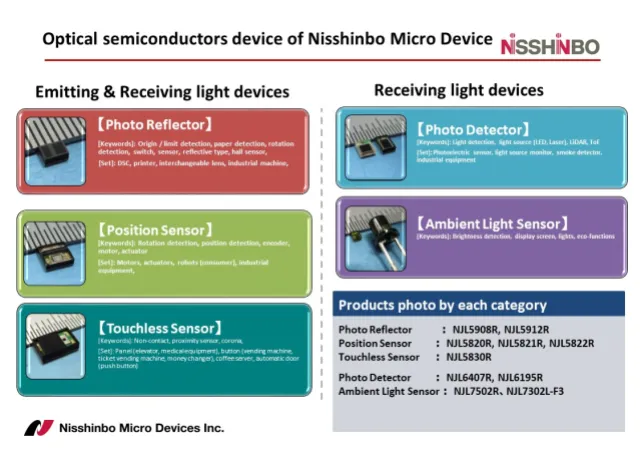

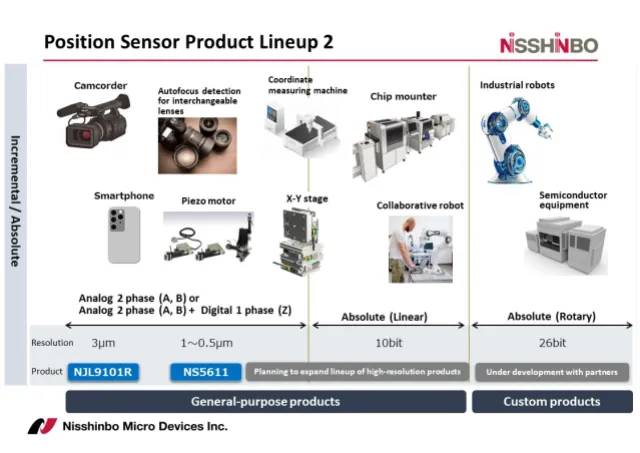

“Optical sensors can achieve high precision in a small form factor that cannot be equaled by magnetic sensors,” says Noda. For example, because optical sensors are less affected by the magnetic field generated by motors than magnetic sensors, the sensor can be positioned closer to the motor and made smaller. Incremental position sensors for high-precision position detection in camera lenses, and absolute encoders for industrial equipment and robots are currently the main applications, and custom products account for approximately half of optical semiconductor-related net sales. What is distinctive about Nisshinbo Micro Devices optical semiconductor products is the way the company listens to the needs of customers, and focuses on high performance, reliability, quality, and ease of use. “We will grow the business by developing even more distinctive products through the trinity of circuit, device, and packaging,” explains Noda. Nisshinbo Micro Devices continues to launch new photodetector, photoreflector, and position sensor products.

Some of the main optical semiconductor products offered by Nisshinbo Micro Devices. Source: Nisshinbo Micro Devices

Using proprietary packaging technology to achieve some of the world’s smallest and lowest-profile photodetectors.

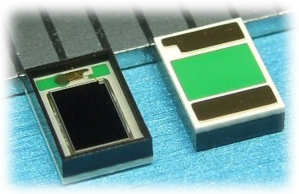

NJL6407R with compact and low-profile design using COB technology. Source: Nisshinbo Micro Devices

The product that symbolizes the photodetectors that are the basis of light sensor modules is the NJL6407R, which is used in Blu-ray drives, RGB wavelength monitors, optical switches, and other applications. Despite being a photodetector with peripheral light blockers, to prevent unintended ingress of light to the photodiode, it measures only 2.0×2.9×0.75mm and achieves an ultra-low profile of less than 1mm.

Generally, photodetectors with peripheral light blockers are packaged in a resin mold created using a die.

Fumiaki Ohno, Advanced Specialized Manager in the Module Design Department of the Technology Development Division

“The NJL6407R uses a type of packaging technology called COB (Chip On Board) in which the resin is flowed around and over ICs mounted on the board” explains Fumiaki Ohno, Advanced Specialized Manager in the Module Design Department of the Technology Development Division. This proprietary COB technology enables precise control over the thickness of the resin as well as flexible adjustments to the position of the light blockers. “Because these are easy to make small and low in profile, a die that is expensive in terms of both cost and time is no longer required, allowing us to tailor form factors to address various customer requests,” says Ohno. In addition to other products, the NJL6401R-3, which achieves an ultra-miniature and low- profile package of 1.2×1.7×0.8mm, has already been commercialized. High-sensitivity photodiode technology and COB packaging technology have made a significant contribution to enhancing the added value of optical semiconductors at Nisshinbo Micro Devices.

Another unique photodetector is the NJL6195R, which is responsive to infrared light. Not only does this use COB technology to achieve an ultra-low profile package of 3.55×3.95×0.82mm, but it also has a large light receiving surface area of 8.88mm2. A larger light receiving surface area makes it easier to position the device in relation to the light-emitting element, resulting in a higher degree of system design flexibility and ease of use.

Making photoreflectors easy to use with high-brightness LEDs

Appearance of NJL5908AR. Source: Nisshinbo Micro Devices

Photoreflectors (also called reflective light sensors or photo interrupters) are modular devices that incorporate a photodiode and a light-emitting element. Nisshinbo Micro Devices has commercialized such products, like the NJL5908AR, which achieves ultra- miniaturization and an ultra-low profile through the use of COB technology in a package measuring just 1.06×1.46×0.5mm. “The NJL5912R, also offered in the same 1.06 x 1.46 x 0.5mm COB package, uses a high-brightness LED that has eight times the brightness of competing products with the same current draw,” notes Ohno. He emphasizes the ease of use of the product. “By combining a high-brightness LED with a phototransistor, we succeeded in creating a highly robust photoreflector, as can be seen by such characteristics as the long focal distance, which is achieved despite low power consumption, and the resistance to noise caused by external light.”

Accelerating initiatives to improve ease of use by reducing the size and lowering the profile of position sensors.

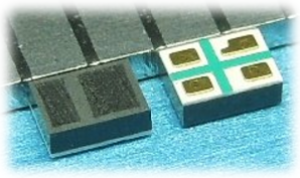

Appearance of NJL5822R. Source: Nisshinbo Micro Devices

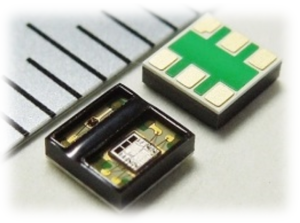

Position sensors, which integrate a signal processing circuit together with a photodiode and light-emitting element, are the area in which the trinity of circuit, device, and packaging achieves its maximum impact.

The NJL582xR series are digital two-phase output position sensors used mainly in encoder applications, offering ease of use through their small size, low profile, and high robustness. The package dimensions are 2.6×2.5×0.8mm. Ohno explains that many position sensors use a lens structure on the upper light-emitting and light-receiving surfaces to enhance the accuracy of position detection. The NJL582xR series combines an OEIC (OptoElectronic Integrated Circuit) incorporating a high-sensitivity photodiode with a high-efficiency, high-brightness LED to achieve a lens-free structure, resulting in superior miniaturization and low profile. “When lenses are used this limits the focal range and makes the relative positioning of the sensor and the reflector critical, but the NJL582xR series mitigates these constraints, giving the customer more leeway in terms of mounting.” The distance between the sensor and the reflector that can be handled by the NJL582xR series is 0.3mm to 5.0mm. The product also has a wide lateral (radial) directional mounting tolerance of ±0.5mm, and can thus be used as an “adjustment-free” solution in a wider range of applications.

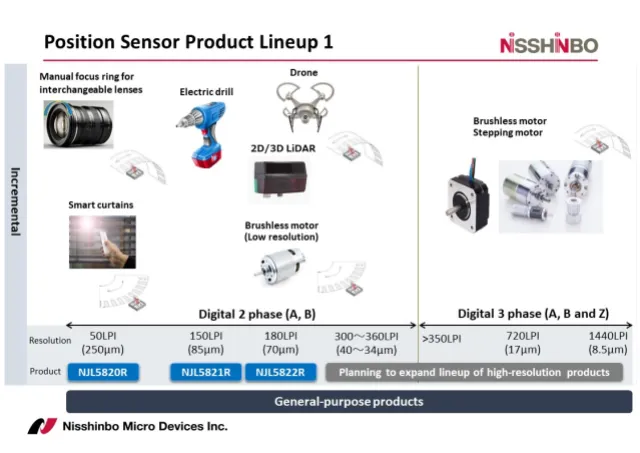

The latest product in the NJL582xR series is the NJL5822R, which has a striped reflector with a resolving power of 180 stripes (180LPI), equivalent to a stripe width of 70μm. An NJL5823R, which can handle 300-360LPI, is also planned. Nisshinbo Micro Devices is also planning products equipped with multiplier circuits to enable higher resolving power capable of addressing 360LPI and higher, as well as products with origin detectors (dual phase + single phase). “We are putting in place a lineup that can cover a wide range of applications for high-precision motors, including DC motors and stepping motors,” notes Ohno.

The development roadmap of position sensors. Source: Nisshinbo Micro Devices.

Developing a variety of opto-semiconductor modules to power further business expansion.

In addition to photoreflector and position sensors, Nisshinbo Micro Devices is developing a range of module products with optical semiconductor technology at their core. Noda explains that Nisshinbo Micro Devices is establishing a system to allow it to respond speedily to the requests of customers and the market. “To enable promotions and marketing to move forward simultaneously, we have set up cross-functional teams for planning, development, and sales that cut across the organization, and which are led from the front line. Moving forward simultaneously with promotions that detect customer needs at an early state to provide the optimal product, and marketing that drives the planning of new products to resolve issues that customers will encounter in the future, enables Nisshinbo Micro Devices to respond speedily.”

“Going forward, we will continue to partner with customers in Japan and overseas with demanding needs, such as those for high-precision motors, actively engaging in joint development and promoting the development of new light sensor modules” he says. “Our goal is to double net sales of optical semiconductor-related products by 2026. Beyond that, we are aiming for further growth in the business and will also explore entry into new markets.”

Ippei Noda, General Manager of the Module Design Department in the Technology Development Division and Fumiaki Ohno, Advanced Specialized Manager in the division

Additional Resources

This article was first published in EE Times on August 7, 2024, and is reprinted here with permission from AspenCore, Inc.

Expanding Business Scope

A Compilation of Nisshinbo Micro Devices Interviews

-

The NA1150 audio amplifier sets a new standard, driving speakers with PWM

-

Introducing definitive industrial sensor AFE ICs by Nisshinbo Micro Devices

-

Actively investing to establish a third pillar of revenues alongside op-amps and power ICs

-

Why Nisshinbo Micro Devices is Expanding ASIC/ASSP Business in Europe

Latest News Highlights

What is myNISD?

myNISD offers a variety of services, including electronic device inquiries, SPICE model downloads, Prime Designer simulations, and on-demand videos.