Featured products

4-Channel Window Voltage Detector with Diagnostic Method

April 15, 2021

Voltage Detectors are widely used to monitor a specific supply voltage and are available in many shapes and sizes. Its general function is to detect a drop in the supply voltage, which may disrupt the proper operation of an application. For certain high reliability applications, this kind of supervision is not sufficient. The R3500 consists of four channels, each with two high accuracy voltage detectors but also with built-in hysteresis that makes the device less sensitive to supply voltage noise and ensures a stable operation. The R3500 monitors whether the supply voltage operates within a specific safe area and provides a reset signal when the supply voltage exceeds an overvoltage or undervoltage threshold. An additional MR pin enables a diagnostic method to verify the proper operation of the voltage detector periodically.

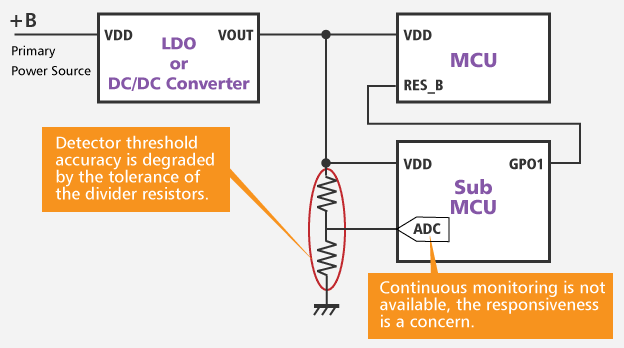

Conventional voltage detectors are usually supervising a low-voltage power supply and its power source (LDO or DC/DC Converter) is commonly shared with the MCU application processor. In case this power source fails or starts up slowly, the voltage detector may fail to operate or has an unstable output.

The design of the R3500 has been enhanced and offers several important benefits:

- The supply and the sense pins are separated, this makes the voltage detector more flexible to measure a voltage within the circuit and at a very low sense voltage level.

- The R3500 has a wide operating voltage range, therefore it can be powered directly from car batteries and function independently from the power source for the processor.

- A built-in voltage regulator makes the voltage detector’s operation independent and stabilizes voltage fluctuations of a car battery, even during a tough cranking condition.

- An additional MR pin makes it possible to periodically check the correct functioning of the monitoring circuit.

-

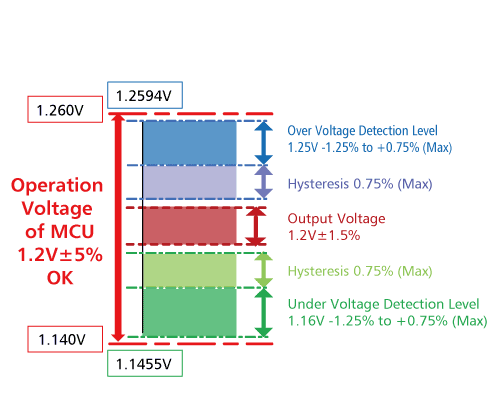

The sense voltage (Max. -1.25 to 0.75%) and hysteresis level (Typ. 0.5%) have a superior accuracy level, this is very suitable to fit into the MCU’s operation voltage specifications including temperature deviations. A malfunction is detected in an early stage; this is especially important for safety critical applications and for automotive systems requiring fault detection including ECU, ADAS, control units including EV inverters and charge controllers.

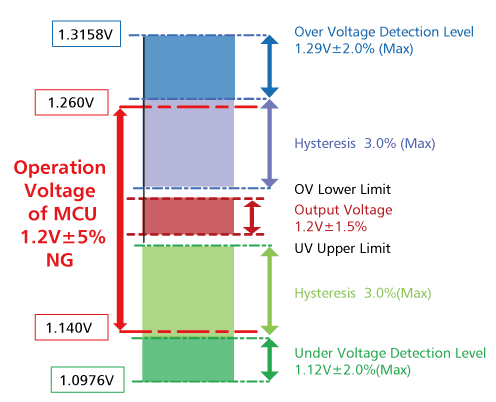

Conventional Technology

Output Voltage = 1.2 V, Set UV = 1.12 V, Set OV = 1.29 V

Hysteresis = 3.0% (Max), Ta = -40°C to 125°C

Lower Accuracy of the OV/UV Detection:

OV/UV monitoring doesn’t meet MCU requirements.R3500

Output Voltage = 1.2 V, Set UV = 1.16 V, Set OV = 1.25 V

Hysteresis = 0.75% (Max), Ta = -40°C to 125°C

Higher Accuracy of the OV/UV Detection:

Able to monitor MCU power supply adding OV/UV monitoring to the existing power supply line. -

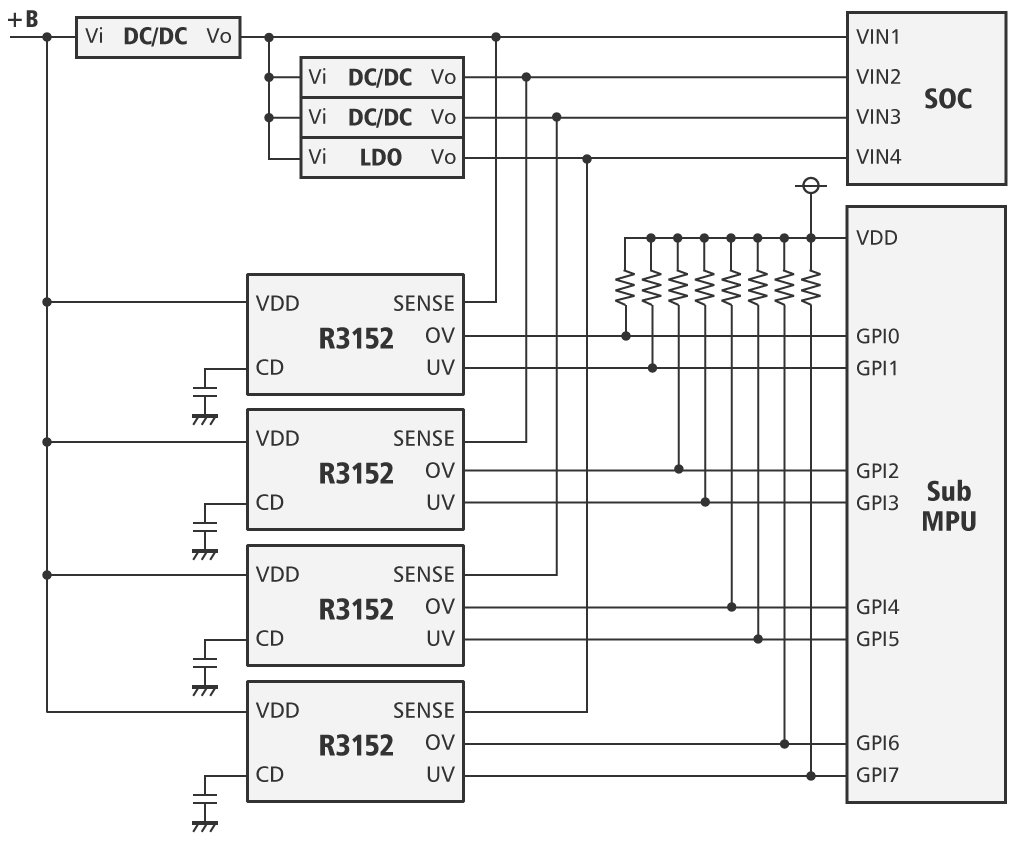

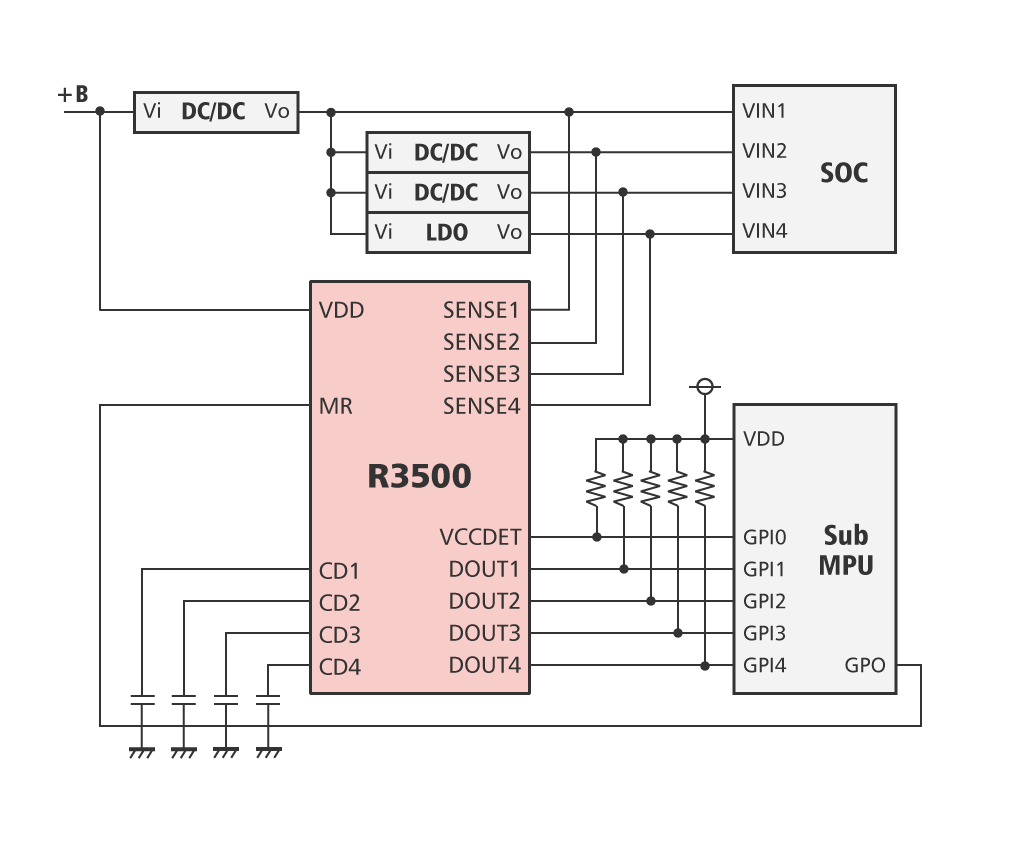

A 4-channel voltage detector simplifies the routing of wires and reduces noise issues caused by multiple Vdd and Gnd wiring when using four single voltage detectors. (see image below)

Conventional reset and window voltage detector ICs require costly external high-precision resistors to obtain a narrow sense voltage range. On the other hand, monitoring with an A/D Converter requires a sensitive resistance to ensure the precision and one cannot measure continuously for an anomaly detection. With the R3500 one obtains a high precision, continuous monitoring system according to the customers demand. Several product versions are available with internally set threshold voltage settings specified in 0.01 V increments.

Output:

As for the output delay time, it can be specified by using an external capacitor connected to the Cd pin. In this way one can set the delay time long enough to reset the processor properly. The R3500 has an N-channel open drain output that needs a pull-up resistor to specify the logical high signal.

Robust design and reliability:

The R3500 has a very robust design and has a secure pin layout as all pins have voltage rating of 20 V and the Vdd pin even up to 50 V (60 V < 200ms) to prevent damage of the chip when adjacent pins are shorted. The R3500 is available in four different quality grades targeting consumer, industrial and automotive markets (AEC-Q100 compliant soon).

Conclusion

The R3500 is intended for use in a wide variety of applications that require a higher degree of reliability; we have product versions available for automotive, industrial, as well as consumer equipment. It monitors for any excessive increase or decrease of the processor’s supply voltage with high accuracy, whereby a failure of the system is detected at an early stage. This is especially important for safety-critical automotive applications because it significantly improves functional safety, useful for ASIL-B / C systems including ECU, ADAS and control units, including EV converters and charge regulators. The R3500 is included in our product longevity program in order to support specific long-term projects; products included in this program remain available for at least 10 years.