News Release

New Voltage Detector: R3154 Series, Maximum 42 V Input Window Voltage Detector Suitable for Use in Functional Safety

Oct. 12, 2020

Ricoh Electronic Devices Co., Ltd.

Ricoh Electronics Devices Co., Ltd. has launched the R3154 series, a maximum 42 V window voltage detector*1 suitable for use in products required to meet functional safety standards.

These days, automotive and industrial equipment must conform to functional safety requirements, and the same applies to electronic components used in those devices. One of the examples is the need for high-accuracy monitoring of power supply for an MCU or an SoC.

We have developed and released the R3154 series in order to correspond to the needs for high-accuracy monitoring. It can monitor both under- and over-voltage of the power supply with high accuracy, suitable for seeing whether the supplied voltage is within the operating voltage range of the load device.

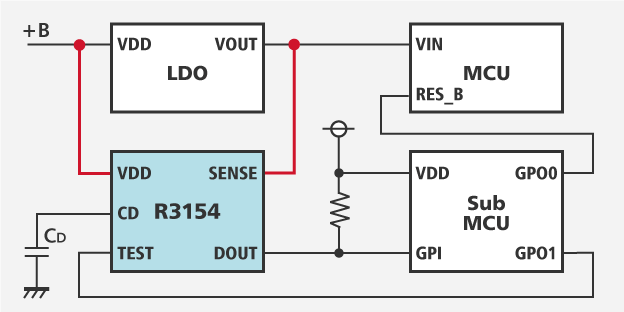

Conventional low input voltage detectors whose input pin also functions as a monitoring pin have a risk of abnormal operation caused by voltage fluctuations in the power supply, as it is not only the monitoring target but also the power source of the detector. The R3154 series solves this problem by increasing the input voltage up to 42 V, which enables the new detector to even correspond to batteries for automotive and industrial applications. Furthermore, separated input and monitoring pins make it possible for the detector to stably monitor power supply voltage even when the monitoring voltage fluctuates largely.

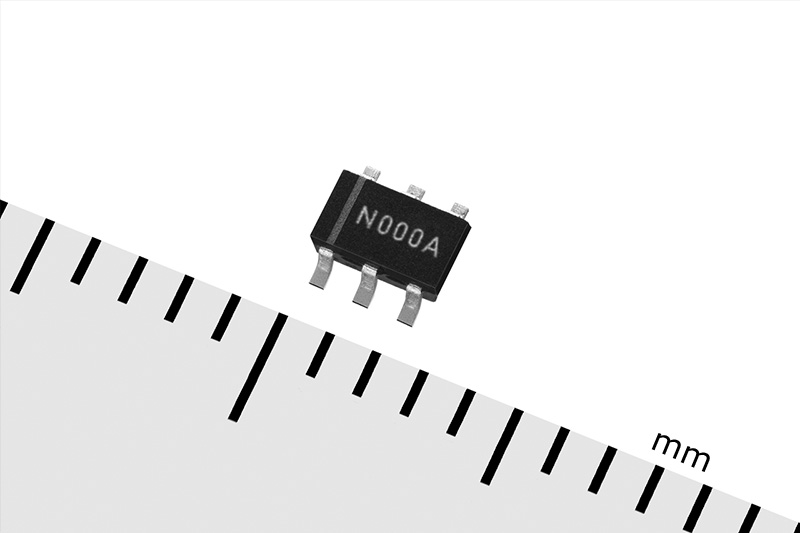

Considering further progress in low-voltage driven SoC development and the growing needs for high-accuracy low-voltage monitoring in the future, the R3154 series can set a lower under-voltage detection voltage than the previous model R3152 series (over-voltage detection: minimum 0.75 V / under-voltage detection: minimum 0.55 V). Also, an additional fault diagnosis function using an MCU and the adoption of SOT-23-6 package considering prevention of a short between pins contribute to achieving the compatibility of safety and miniaturization.

*1 A detector monitoring both under- and over-voltage of the power supply voltage

R3154 Series (SOT-23-6)

Key Features of R3154 series

1. Window Voltage monitoring and Brief Fault Diagnosis Function

This IC can monitor under-voltage and over-voltage at the same time, and therefore decrease the number of voltage detectors added so as to meet functional safety standards.

The R3154 series has a lower under-voltage detection voltage range than the R3152 series. Also, it is equipped with a self-diagnosis function using MCU pulses, making it possible to check whether the detector is normal or out of order.

2. High Detection Accuracy and High Hysteresis Accuracy

The R3154 series achieves high detection accuracy of ±0.5% (Ta=25°C) and of 1.25%/+0.75% (-40°C to 125°C) and high hysteresis accuracy of typ. 0.5% (max. 0.75%). The detection voltage value is user-settable in 0.01 V step, enabling optimal and high-accuracy power supply monitoring according to the system.

3. High Input Voltage Pin and Separated Voltage Monitoring Pin

With the maximum 42 V input and input rating of 50 V, the R3154 series can directly receive its operating voltage from high-voltage batteries used in automotive and industrial products. Separation of the monitoring function from the input pin enables the new IC to stably detect abnormality regardless of monitoring voltage fluctuations.

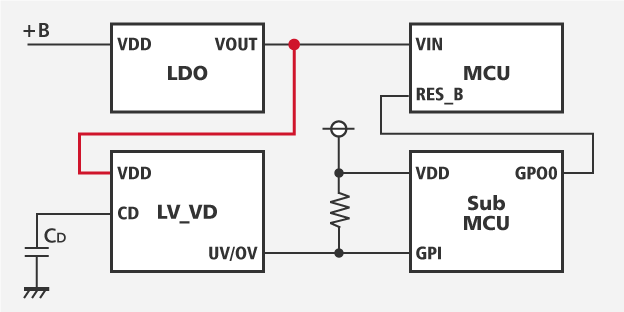

Conventional Product

Provides a LDO Output as a Power Source:

Risk of operating abnormally when LDO outputs abnormally. Becomes unstable state when LDO starts-up slowly.

Depending on LDO → Safety problem

R3154

Provides a Battery as a Power Source:

Being powered by +B, the R3154 series can operate normally even when LDO outputs abnormally. As voltage monitoring starts before LDO start-up, output voltage is monitored normally.

Not depending on the LDO state → High safety

4. Package Preventing Short between Pins

The R3154 series adopts SOT-23-6 package considering pin assignment for preventing a short between adjacent pins, and thus enables further safety design.

Quality Grades of R3154 series

| Grades | Applications | Operating Temperature Range | Test Temperature | ||

| Low | 25°C | High | |||

| Automotive, Class R | Safety-critical Parts and General Equipment (Body System) | −40°C to 125°C | |||

|---|---|---|---|---|---|

| Automotive, Class A | Accessories | −40°C to 125°C | |||

| Industrial, Class Y | Industrial Equipment | −40°C to 125°C | |||

| Consumer | Consumer Equipment | −40°C to 105°C | |||

* Quality class R products undergo reflow stress screening.

Related Links

Electrification of automobile by RICOH power management IC

RICOH's approach to safety mechanisms, contributing safety and reliability of in-vehicle devices.

We will provide IoT systems with semiconductor devices that feature low supply current, low noise, and small size by the highest level of CMOS analog technology, and strengthen your competitive edge.